made by skilled people

SMART FASHION MANUFACTURING

made by skilled people

SMART FASHION MANUFACTURING

We provide end-to-end digital garment production services – from pattern preparation through digital modeling and 3D fitting to final manufacturing. Our digital solutions not only accelerate the process but also make it more sustainable.

Our product development process enables us to work with detailed visualization and technical precision from the early design phase. By combining 2D technical drawings and 3D digital models, we minimize the risk of errors, accelerate sampling and production processes, and ensure more accurate communication with our partners.

Upon request, we create 3D digital garment models that allow designers and clients to review the product’s appearance before sample development and production begin. This makes it possible to apply visual adjustments early on, helping reduce sampling costs and limiting the number of unnecessary physical prototypes.

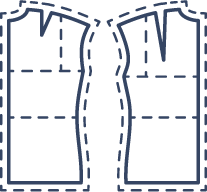

Our patterns are created and optimized digitally, considering garment function, fabric properties, cutting requirements, construction techniques, and manufacturing specifics. This approach maximizes both accuracy and efficiency in the pattern development and production phases.

We simulate garments on digital avatars representing various body types using 3D fitting technology. This allows us to detect and correct fitting issues before physical sampling begins, saving time, materials, and production costs.

If needed, we prepare detailed spec sheets for each product, including materials, components, sewing techniques, and manufacturing instructions. This document is essential for accurate sampling and consistent production.

We define and record the key measurement points of each garment in a standardized table — such as bust, waist, shoulder width, etc. These measurements guide the sample development, production, and quality control processes.

We provide customized production specifications that include agreed construction details, quality expectations, and standardization guidelines from the pattern development stage. This ensures consistent quality without unnecessary waste — supporting more conscious manufacturing.

Grading defines how each size differs from another while preserving the original proportions and essence of the design. Using digital tools, we create accurate and consistent size variations efficiently. Our automated digital grading process ensures that each size follows the required standards—whether based on European, American, or custom sizing systems. This precise approach lays the foundation for garments that fit beautifully across all body types.

We maintain a library of digital pattern blocks that can be quickly customized for different models. This significantly speeds up the development process while maintaining consistent quality.

We use digital models (avatars) for 3D fittings that represent various body shapes and sizes, which can be customized according to the client’s requirements. These helps ensure that garments fit the intended target group accurately.

We export our patterns in the widely accepted industry-standard DXF format, making them compatible with digital systems and partners using digital plotters. For clients who are unable to receive digital files, we also offer printed patterns—available on single-sided fusible adhesive paper or cardboard upon request. This flexibility ensures that partners with varying technical setups can seamlessly integrate into the development and production process.

Our 3D digital collection presentations showcase realistic garment models customized with fabrics, logos, embroidery, prints, trims (buttons, zippers), and visible stitching details. Final 3D avatars can be delivered as image files. These digital lookbooks and presentation materials are ideal for internal reviews, sales tools, or online campaigns—helping accelerate time to market.

We also offer support for brands that have previously worked with hand-drawn, paper-based patterns. Our system can import these physical patterns into a digital format, allowing seamless integration into our workflow. This is especially beneficial for smaller or emerging labels, or designers who create unique patterns by hand, as the digitized files can then be edited, reused, shared, or printed much more efficiently.

Our services include pattern making, production of garment labels and packaging, as well as comprehensive logistics solutions such as warehousing and transportation. While clothing design is done by our clients, we provide support throughout all phases of modeling, pattern development, manufacturing, and delivery.

Yes, we fulfill custom orders tailored to individual needs—whether it’s a small batch or a large-volume production.

We welcome inquiries from both individuals and companies. We offer personalized solutions for everyone.

We deliver the finished products according to our partners’ needs (B2B and B2C options available), either partially or fully, to domestic and international addresses.

Yes, we store finished products securely in our own logistics facility and also provide 3PL (third-party logistics) services.

Yes, we provide regular updates on order status, and detailed tracking is available upon request.

It depends on the complexity, quantity, and current capacity of the project, but we always aim for the shortest possible lead time.

We prefer digital formats (e.g., PDF, DXF), but we also accept paper-based patterns. After receiving the samples, we always coordinate the details.

Yes, we can create a digital pattern based on a provided garment, which we then adjust according to the client’s needs.

Yes, we can provide a pre-production sample upon request. Production begins after client approval.

Optional addition: This process can also be replaced by 3D modeling, if the client accepts our 3D sample quote in advance.

Yes, we prepare detailed specifications and documentation for each project, ensuring full transparency throughout the process.

We can source base materials upon agreement, but clients may also provide their own. Accessories (thread, zippers, buttons, clasps, etc.) are included in the quoted price. Labels and packaging are at the client’s expense, but we handle the development and production.

Absolutely! Custom labels, packaging materials, and branding solutions are available. Clients must provide the design or concept.

General support is available on weekdays, but for urgent matters, weekend availability is possible by prior arrangement.

We would love to speak with you.

Join our mailing list for exclusive previews, refined design insights, and curated updates from behind the scenes.